Chamwe Kaira

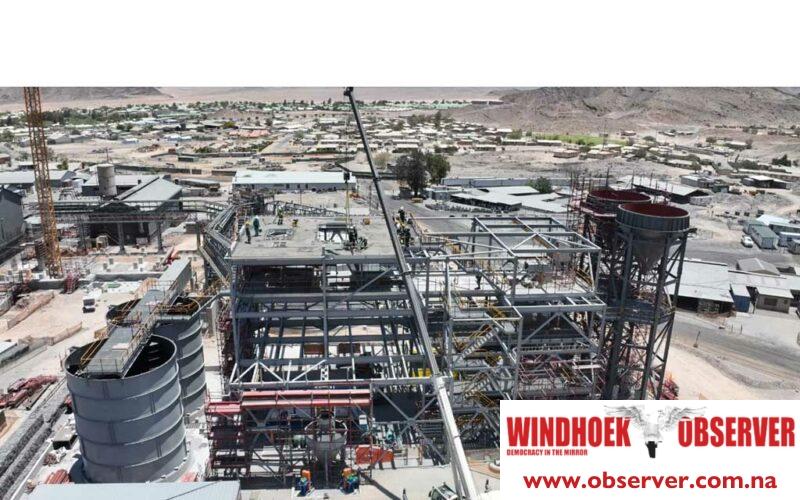

Rosh Pinah Zinc says its Rosh Pinah 2.0 expansion project has reached 75% completion.

The construction of the paste fill and water treatment plants is finished, and both are now being commissioned.

“It is anticipated that both these plants will be handed over to operations early in the first quarter of 2025,” the company said.

The underground piping and boreholes needed to distribute paste to the first trial stope have been installed. Barricading for the stope is complete, and all control instruments have been connected to the new control system through SCADA.

The company said earthworks and civil works for the SAG mill and flotation cells have been completed.

Steel erection and flotation cell installation are underway. A new surface primary crusher has also been installed.

Construction of the new 600PAX change houses is ahead of schedule.

Over 50% of the poles for a 20-kilometre overhead powerline—needed to supply additional electricity for the commissioning of RP 2.0—have been completed.

“We are proud to share these advancements with you and are looking forward to the continued progress of these state-of-the-art facilities at Rosh Pinah Zinc,” the company said.

The Rosh Pinah 2.0 project includes new processing facilities, a paste fill plant, a water treatment plant, and a dedicated portal and decline to access deeper deposits.

Once completed, the project will increase mill throughput from 700,000 tonnes to 1.3 million tonnes of ore per year. This will boost average annual zinc equivalent production to 170 million pounds.

The Chamber of Mines of Namibia’s 2024 annual report noted improved safety practices underground, including better ground support and

In processing, the addition of zinc and lead scalping to the circuit improved early recovery rates.

The mine also focused on dust mitigation.

Key initiatives included cladding the tailings facility with rock, paving roadways, installing wheel wash stations, enhancing water suppression systems at the crusher, and rehabilitating nearby community areas.