Allexer Namundjebo

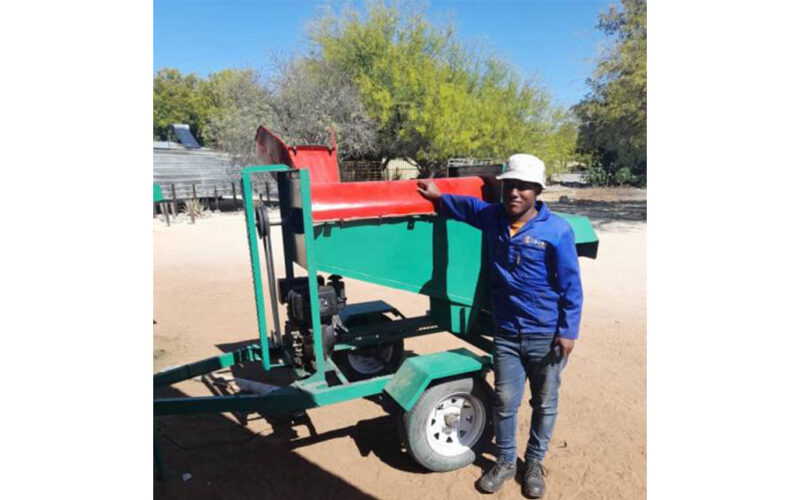

At the age of 23, Marshall Aibeb from the Hai//om San community has built a mahangu threshing machine to help farmers during harvest season.

The machine simplifies the difficult and time-consuming process of threshing mahangu, also known as pearl millet.

Aibeb is a level 2 metal fabrication student at the Community Skills Development Foundation (COSDEF) in Ondangwa.

He received a scholarship from the Palms for Life Fund, which supports youth in marginalised communities.

“I enrolled at COSDEF the year before last through the Palms for Life Scholarship, and I started my internship this March. I’ll finish in August,” Aibeb said.

He has already built six threshing machines and plans to start his own business after completing his training.

His business will focus on manufacturing agricultural and household metal products, such as threshers, trailers, braai stands, window frames, and door frames.

“We created the thresher to help people harvest their mahangu more easily. Many still use traditional methods, which are physically demanding and time-consuming. Our machine is designed to save both time and energy,” Aibeb explained.

He thanked the Palms for Life Fund for giving him the chance to grow. “They’ve helped me grow, learn new skills, and explore places I never imagined,” he said.

Aibeb is doing his internship with H.G. Holdings in Ondangwa, where his supervisor, Christof Shilongo, is impressed with his work.

“He is very skilled. We’ve tested him, and he can build a thresher machine without supervision,” said Shilongo, who hopes to employ Aibeb after the internship ends.

Aibeb is one of 1,200 young people receiving vocational training at COSDEF through support from the Palms for Life Fund.

The programme aims to equip Namibians from underserved backgrounds with practical skills, focusing on agriculture, tourism, and manufacturing.

A mahangu threshing machine processes pearl millet and comes in different sizes.

Small models cost about N$25,000, while larger trailer-mounted versions go for around N$55,000.

To build one, fabricators use angle irons, shafts, small engines, pulleys, metal sheets, round bars, flat bars, nuts, and perforated metal sheeting. With the right skills, a thresher can be made in one to three days.

The shaft is the core of the machine. When powered by the engine, it spins rapidly, using welded hooks to separate the grain and produce clean mahangu seeds.

A mat at the intake prevents the grains from flying out due to the shaft’s speed.

This machine is becoming popular among Namibian farmers. It boosts productivity and offers a modern way to process mahangu, replacing traditional pounding methods.